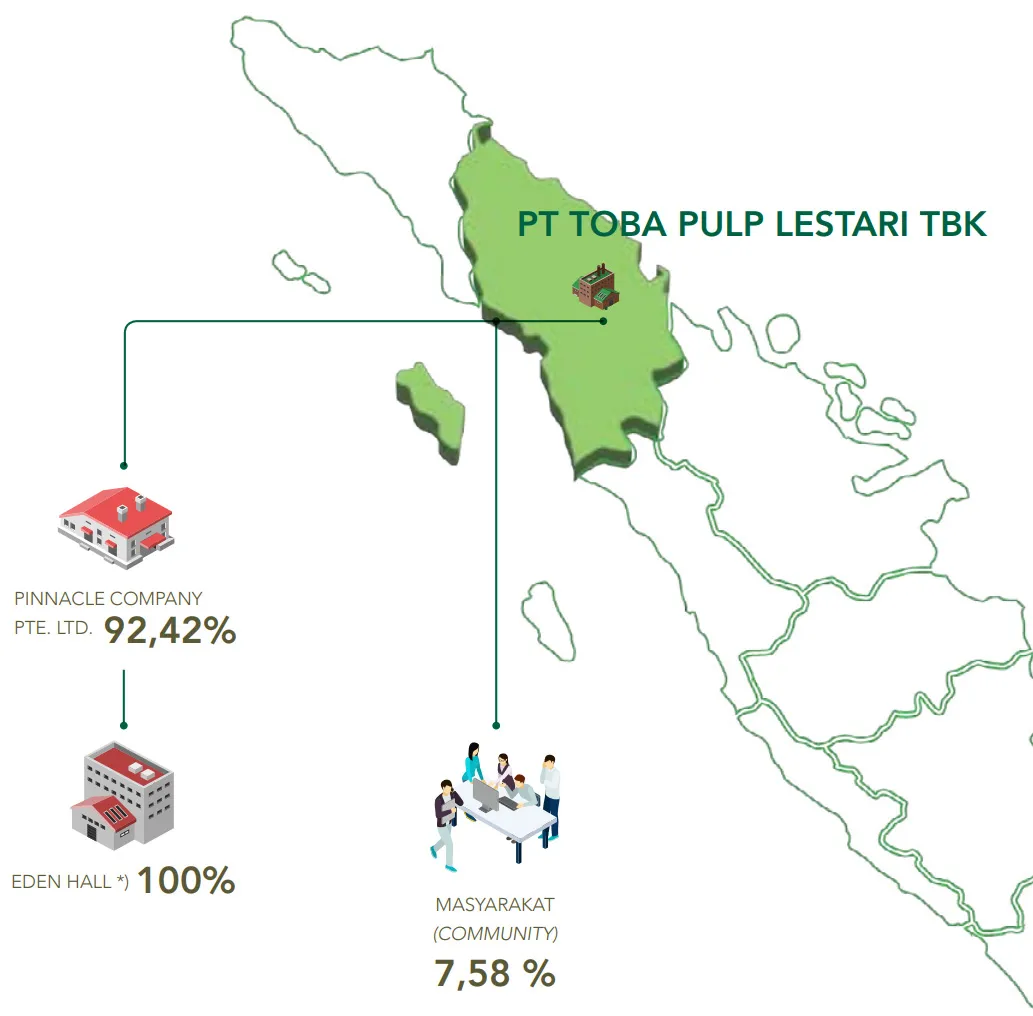

Our Business Overview

Catatan: *) Entitas induk terakhir adalah Eden Hall Ltd. Bapak Joseph Oetomo mengendalikan baik langsung maupun tidak langsung Eden Hall Ltd.

Note: *) Ultimate parent entity is Eden Hall Ltd. Mr. Joseph Oetomo controls both direct and indirect Eden Hall Ltd.

History of Establishment

PT Toba Pulp Lestari Tbk (“Company”) was established in the framework of the Domestic Investment Law No. 6 of 1968 jo. Law No. 12 of 1970 based on deed No. 329 dated April 26, 1983 from Misahardi Wilamarta, SH, a notary in Jakarta. The deed of establishment was approved by the Minister of Justice of the Republic of Indonesia in his decision letter No. C2-5130.HT01-01 TH.83 dated July 26, 1983, and announced in State Gazette of the Republic of Indonesia No. 97 dated 4 December 1984, Supplement No.1176.

The Company’s Articles of Association have been amended several times, and most recently by Deed Number 06 dated 19 June 2019 from Gunawati, SH, a notary in Deli Serdang Regency. The Articles of Association have been approved by the Minister of Law and Human Rights of the Republic of Indonesia in its decision letter Number AHU.0032845.AH.01.02.T 2019 dated June 25, 2019.

Company Business Activities

In accordance with article 3 of the Company’s Articles of Association, the scope of its activities is to carry out business activities of the Pulp and Chemical Industry to support the pulp industry (including but not limited to chlorine dioxide, chlorine, hydrochloric acid, caustic, nitrogen, oxygen, and sulfur dioxide), Concession of Plantation Forest (includes Eucalyptus Forest Exploitation, Eucalyptus Plant Breeding, Other Forest Concession, and Other Forestry Plant Breeding Exploitation), Timber Goods Industry (including but not limited to primary industry of wood forest products in the form of processing logs into wood chips and other wood products which have not been previously covered), Large Trade in Basic Chemical Materials and Goods, Bounded Warehousing Activities or Bonded Zone Areas, both Bonded Zones within one stretch and Bonded Zones outside the overlay, specifically for activities Companies related to these businesses but above, as well as other activities to support the above business activities, including but not limited to all other business activities to support the raw materials and operational activities of the aforementioned business activities as well as marketing of the products of all the Company’s business activities.

Company Licensing

Operating Permit

- SK Number: 8120011192845

- KBLI Name / Code: Eucalyptus Forest Exploitation 02118

- Exploitation of Eucalyptus Plant Breeding 02148

- Pulp Industry 17011

- Basic chemical industry of inorganic chlorine and Alkali 20111

- Other Inorganic Basic Chemical Industry 20114

- Macro-nutrient fertilizer industry made in Primary 20122

- Artificial Staple Fiber Industry 20302

Investment License

- Foreign investment

- SK : Notification of Presidential Decree No. 07 / V / 1990 of May 11, 1990

- Agency : Chair of the Investment Coordinating Board

- Industrial Business License

- SK Number : 627/T/INDUSTRI/1995

- Agency : Chair of the Investment Coordinating Board

- Industry : Pulp

- Production : Pulp

- Capacity : 165,000 tons with tolerances exceeding 30%

Forest Utilization Business Licensing

- SK Number: Minister of Forestry Decree No. 493/Kpts-II/92 dated June 1, 1992 concerning Granting of Industrial Plantation Forest Concessions, and has been amended several times, and the latest by Decree of the Minister of Environment and Forestry of the Republic of Indonesia Number SK.307/Menlhk/Setjen/HPL.0/7/2020 concerning the Seventh Amendment to the Decree of the Minister of Forestry Number 493 / KPTS-II / 1992 dated June 1, 1992 concerning Holders of Industrial Plantation Forest Concession Rights to PT Inti Indorayon Utama, as follows:

- Industry: Plantation Business

- Production: Eucalyptus wood

- Area: 167.912 hectares

- Border Decree: Minister of Forestry Decree No. SK.821 / Menhut-VII / KP / 2004 April 19, 2004 and Decree of the Minister of Forestry of the Republic of Indonesia No.SK.704 / MENHUT-II / 2013 dated October 21, 2013